New Energy

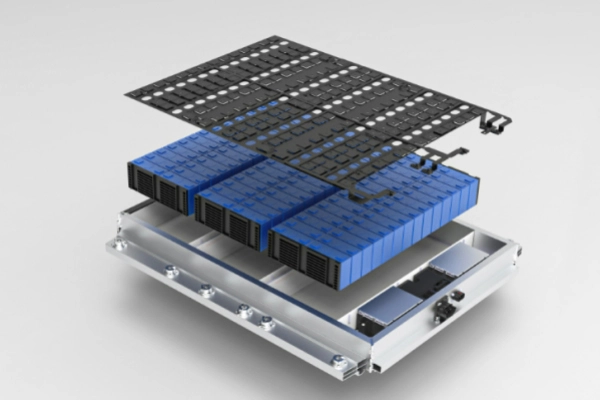

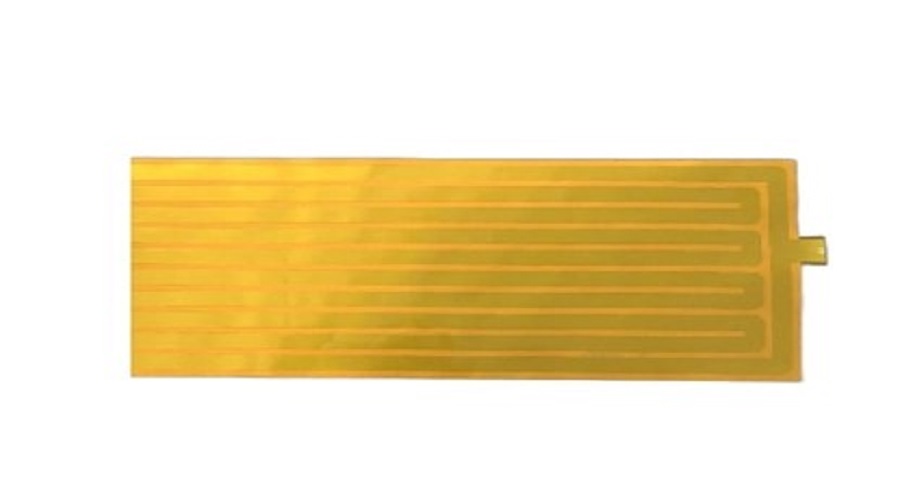

At the beginning of the rise of new energy vehicles, Bolion Tech established a special battery pack FPC application R&D team and group in Xiamen, specializing in power battery data sampling, and successfully developed a battery pack FPC solution, which mainly solves the problems of messy wiring harnesses, temperature collection, circuit protection, etc. of battery packs. After being launched on the market, Bolion Tech’s battery pack FPC solution has been favored by many power battery companies. Many well-known domestic power battery companies have adopted the solution provided by Bolian Technology, which has been installed in the whole vehicle for use. Unleash the potential of new energy with our FPCs and ccs battery cell module solutions, designed to empower the next generation of sustainable solutions. With the agility to adapt and the resilience to endure, our products are the catalysts for a greener tomorrow.

The bolion Tech’s innovations in the FPC new energy market have led to significant advancements in the application of FPC in new energy vehicles. Our FPC for EV vehicles and FPC for new energy automobiles are specifically designed to meet the rigorous demands of modern electric vehicles. The FPC BMS (Battery Management System) ensures optimal performance and safety, while our cell contact system for EV battery module provides reliable and efficient connections. The CCS solution for EV battery further enhances the integration and functionality of our products. As a leading fpc supplier in the new energy FPC sector, Bolion Tech continues to drive innovation and excellence in the FPC for new energy vehicles industry.

English

English Ελλάδα

Ελλάδα

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China