The Hot-Press CCS Integrated Busbar (IBB) mainly consists of a signal acquisition component FPCA (Flexible Printed Circuit Board Assembly), PET, copper and aluminum busbars, connectors, etc. They are connected into a whole through a hot-pressing process.

IBB is used in new energy electric vehicles (EV), hybrid electric vehicles (HEV), or energy storage battery modules (BESS) to achieve high-voltage series-parallel connection of battery cells, temperature sampling of the battery, and voltage sampling of the battery cell. The FPC component collects this data and transmits temperature and voltage information to the BMS system via connectors, making it a part of the BMS system.

In the early stages of the CCS industry, products were mainly injection-molded holder with wiring harness sampling. With continuous innovation in battery structure, CCS signal acquisition components and integration processes have also been constantly evolving. Currently, CCS signal acquisition components include PCB, FPC, FFC, FDC, etc., and the integration processes include injection molding holders, vacuum forming, hot pressing, and PC die-cutting, forming a situation where multiple technological routes develop in parallel.

The CCS integrated busbar (IBB) hot pressing process involves assembling raw materials such as the signal acquisition component FPC, aluminum bars, and PET insulation film. These materials are then placed in the working area of a hot press machine. By applying a certain temperature and pressure, the aluminum bars and signal acquisition components are pressed into a thin sheet. The electrical connection between the nickel sheet and the aluminum bars is then achieved through welding. This is followed by visual inspection, electrical performance testing, and other tests before packaging and warehousing.

The Hot-Press CCS Integrated Busbar (IBB) can effectively reduce the product size and weight, as well as minimize the number of components. This leads to a more compact, organized overall structure with high integration and reliable insulation sealing. It can achieve automated assembly, helping to improve the space utilization and production efficiency of battery modules, aligning with the industry's trends towards lightweight, integrated, and larger modules.

Both the CCS riveting solution and the CCS integrated busbur hot-pressing solution have their own merits, and the specific choice should be matched according to the customer's actual needs.

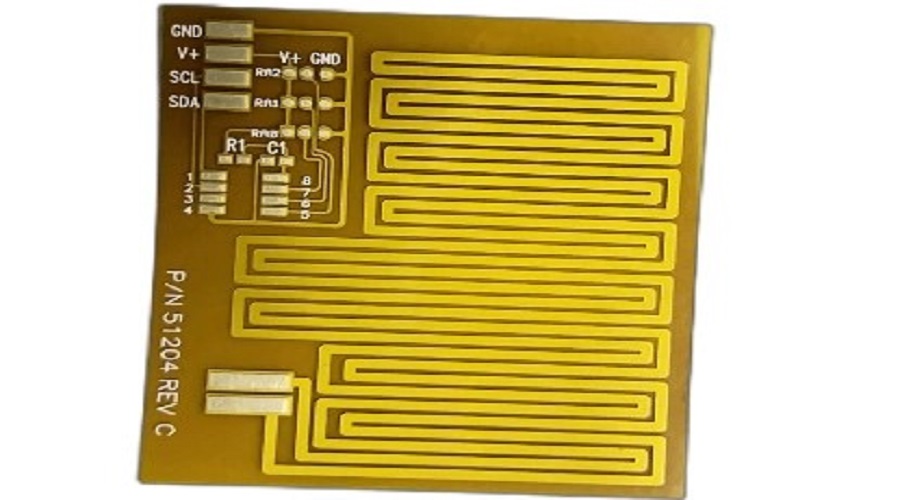

Analysis of the Manufacturing Process of Flexible PCB Heaters

24 Apr 2025

What is a Flexible PCB Heater?A Flexible PCB Heater is a heating element based on flexible printed circuit boards (FPC). It uses a polyimide (PI) or polyester (PET) substrate and forms a metal heating...

Analysis of the Manufacturing Process of Flexible PCB Heaters

24 Apr 2025

What is a Flexible PCB Heater?A Flexible PCB Heater is a heating element based on flexible printed circuit boards (FPC). It uses a polyimide (PI) or polyester (PET) substrate and forms a metal heating...

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China