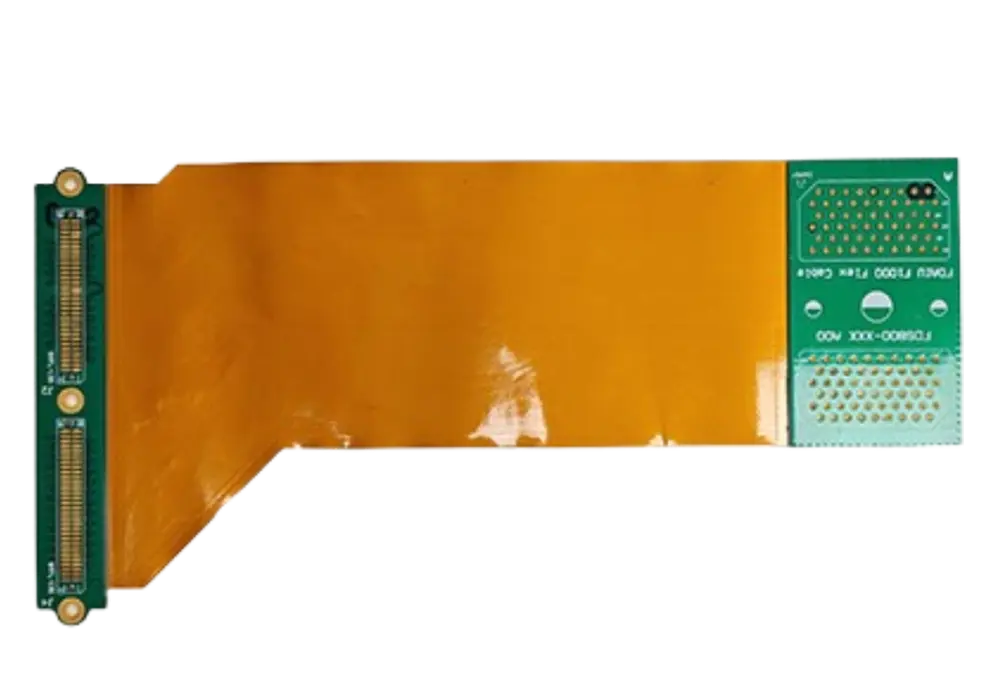

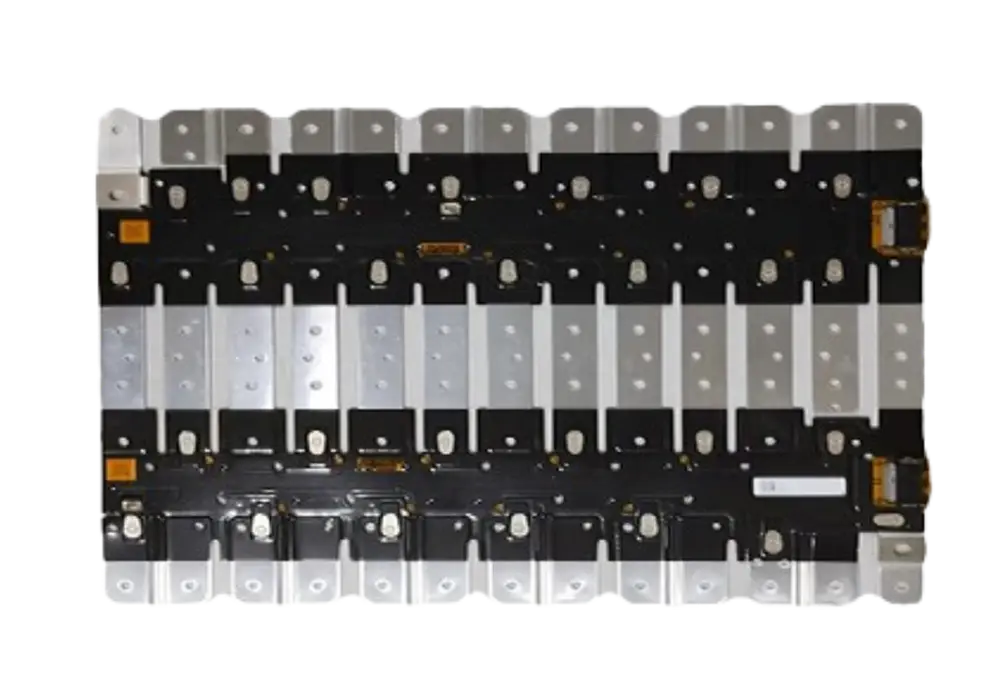

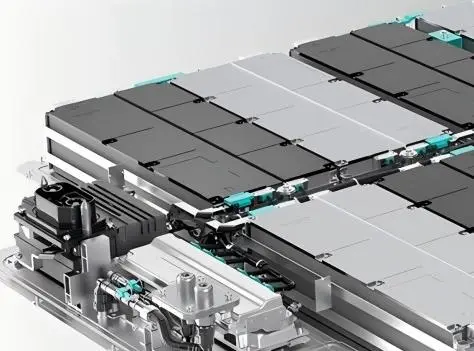

We have the world's most advanced production processes and technologies for FPC and new energy module products, a complete quality assurance (QA) system, a standardized and modern management system and an honest and motivated team, which ensures that we can provide customers with reliable and satisfactory products.

Focusing on mid-to-high end application areas, our products are widely used in fields such as automobiles, new energy, aerospace, medical devices, communications, cameras, optoelectronic instruments and meters, computer peripherals, and LCDs.

Covering an area of 30,000-square-meter clean production workshops and four production bases, with advanced and well-equipped FPC production and test facilities, bolion are currently able to support 40,000-square-meter monthly capacity.

Bolion has the capabilities of producing super long and large FPC, complex and special FPC like up to 12-layer rigid flex pcb, and more than 100 utility models and FPC/CCS patents.

Bolion, as one of the industry role models, is currently a member of the executive directors of the China Printed Circuit Association (CPCA).

Bolion has fully passed certifications of ISO9001 quality management system, TS16949 automotive supply chain management system, ISO13485 medical device system and ISO14001 environmental management system. The FPC series products have obtained the UL certification of the U.S.A. Safety Laboratory Center and have passed the SGS test and identification to meet the requirements of RoHS & WEEE environmentally friendly protection.

Bolion has highly demanding product on-time delivery rate, comprehensive product yield rate and qualification rate, high-standard environmental goals, efficient and pragmatic 6S management method, on-time, fast and reliable after-sales service.

The delivery dates of products are as follows:

Single-Sided FPC:

FPC Prototype (≤1㎡): 2-7 WDs

FPC Stand Turn (2㎡≤ x ≤15㎡): 6-10 WDs

SMT Assembly: 2-5 WDs

CCS/IBB: 2-7 WDs

Double-Sided FPC:

FPC Prototype (≤1㎡): 4-7 WDs

FPC Stand Turn (2㎡≤ x ≤15㎡): 8-12 WDs

SMT Assembly: 2-5 WDs

CCS/IBB: 2-7 WDs

Multilayer/ Air-Gap FPC:

FPC Prototype (≤1㎡): 6-10 WDs

FPC Stand Turn (2㎡≤ x ≤15㎡): 8-13 WDs

SMT Assembly: 2-5 WDs

Rigid-Flex Board:

FPC Prototype (≤1㎡): 6-12 WDs

FPC Stand Turn (2㎡≤ x ≤15㎡): 10-16 WDs

SMT Assembly: 2-5 WDs

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China