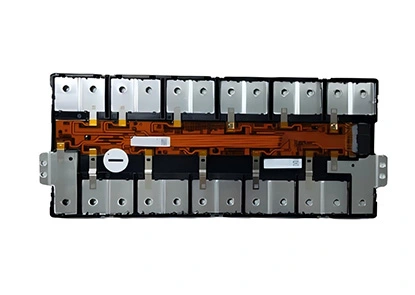

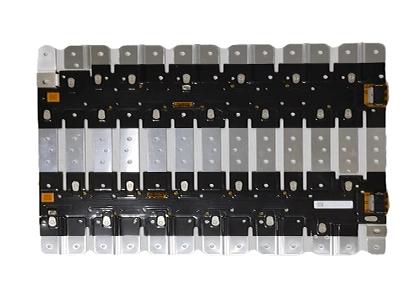

The CCS battery module assembler from Bolion CCS battery module supplier combines signal acquisition components, plastic structural parts, and copper-aluminum bars, which are connected by hot riveting CCS integrated busbar or hot pressing processes. It is used in new energy vehicles and energy storage battery modules to realize series and parallel connection of CCS battery cells, temperature and voltage sampling, and transmit information to the BMS system. As an internal electrical connection component of the battery pack/module, the sampling components, production process, material selection, etc. of CCS is affected by factors such as the battery cell grouping method, battery pack calibration parameters, use environment, space, and weight. Therefore, in order to meet the diverse needs of the application end, CCS products are also constantly upgrading signal acquisition components, optimizing integration processes, etc., and have developed a variety of technical routes, including wiring harnesses, PCB, application of fpc in ev battery, FFC, FDC and other sampling solutions, as well as injection molding brackets, arraying, PET hot pressing films, CCS module blister packaging, and other integration solutions. Additionally, the hot riveting CCS module, injection-molded CCS integrated busbar, and hot press CCS integrated busbar are crucial for the CCS integrated busbar for EV battery systems, ensuring robust and reliable connections. The role of a reliable fpc supplier is paramount in these advancements, as the integration of fpc pcb technology significantly enhances the performance and reliability of EV battery systems.

CCS battery modules are renowned for their exceptional safety and reliability.

Strict Quality Control

Each battery module undergoes rigorous quality testing to ensure stable performance across various applications.

Advanced Manufacturing Processes

Utilizing state-of-the-art manufacturing techniques, we ensure high efficiency and long lifespan for our battery modules.

Multiple Safety Protections

Equipped with multiple safety mechanisms such as overcharge, over-discharge, and short-circuit protection, ensuring safety during use.

Extended Lifespan

Through optimized design and material selection, our battery modules offer a long service life, reducing the frequency of replacements.

With their high safety and reliability, CCS battery modules are the ideal choice for a wide range of applications. Whether you need batteries for electric vehicles or energy storage systems, CCS battery modules provide the most dependable solutions.

The CCS is designed for the interconnection of the individual battery cells in the battery module.

The power battery of EV is composed of several single cells connected in series and parallel. The connection of cells is the key technology for the power battery group. The CCS can realize the functions of high-voltage series and parallel connection of cells, temperature sampling of batteries, cell voltage sampling, etc., and provide temperature and voltage to the BMS system through signal acquisition components and connector components.

The traditional wire was changed to FPC, manual wire bonding, manual welding will enable more excellent integration and automation. FPC can directly integrate fuses and temperature sensors, which can significantly reduce the process complexity of the wire module. The weight and cost are significantly reduced.

CCS (Cell Contacting System) highly integrated functional components such as FPC (signal acquisition component)+ cell isolation cover + copper aluminum busbar +NTC thermal element +fuse + connector.

There are three common packaging methods: cylindrical cells, prismatic cells, pouch cells. Each battery cell type has its own pros and cons.

CCS battery module with injection plastic holder; CCS battery module with blister molding holder; CCS battery module with hot-press PET film; hot-press CCS module; lightweight IBB module.

CCS, which uses FPC and other signal acquisition components, has the advantages of light structure and high integration, which is conducive to improving the space utilization and assembly efficiency of the battery pack. It is in line with the trend of lightweight automobiles, system integration of components and large modules. The rapid development of new energy vehicles will drive a substantial increase in the demand for FPC for automotive power batteries. Therefore, CCS has broad application prospects.

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China