Compared to traditional heating methods, heating elements can more effectively utilize energy, be more efficient, energy-saving, and safe, because they can achieve precise control of heating temperature, provide uniform heat distribution, achieve rapid heating, and are supplemented with overheating protection and insulation characteristics considerations and designs. It can be customized according to your needs to adapt to heating scenarios with different environments, geometries, sizes, and power requirements, meeting the multiple needs of modern people. It has a wide range of functions, not limited to heating, but can also be used for antifreeze, defrosting, dehumidification, etc. Its ease of installation is also evident. The application of flexible pcb in heating elements, especially when sourced from a reliable fpc supplier, enhances the versatility and efficiency of fpc pcb in various heating and temperature control scenarios.

By choosing the right material and design, you can ensure that the heater performs optimally in a specific application while extending its service life.

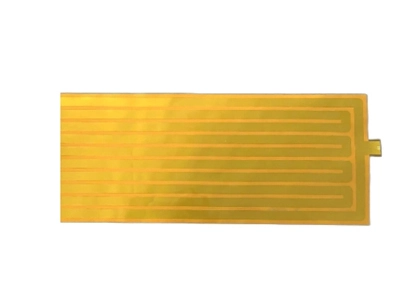

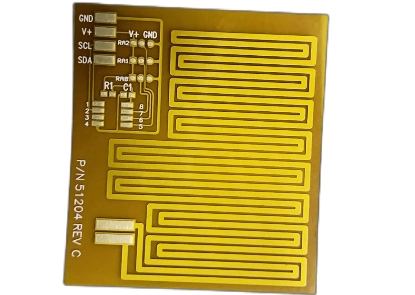

Silicone rubber heaters are suitable for heating applications that require shape customization and harsh environments due to their good flexibility and weather resistance, while PI heaters are suitable for applications that require high-precision temperature control due to their excellent thermal conductivity and resistance stability.

Silicone rubber heaters: They can be used in large areas and leaky environments. Silicone has better long-term temperature resistance than PI heaters and is suitable for applications that require high temperature resistance and uniform heating, such as industrial equipment and medical equipment.

PI heaters: They are suitable for applications that require small area, light weight, softness, and high-temperature insulation, such as new energy batteries, communication equipment, etc., or where the heater is exposed to vacuum, radiation, oil or certain chemicals.

Compared to traditional heating methods, heaters can more effectively utilize energy, be more efficient, energy-saving, and safe, because they can achieve precise control of heating temperature, provide uniform heat distribution, achieve rapid heating.

According to the material, they can be divided into PET heaters, PI heaters, silicone heaters, aluminum heaters, epoxy heaters, PTC heaters, graphene heaters, and carbon fiber heaters. Bolion mainly produces PI heaters and silicone rubber heaters.

(1) Automotive industry: Heaters are used in low-temperature protection of new energy vehicle battery packs, automotive paint booths, dispensing robots and other equipment to keep the equipment working normally in cold weather.

(2) Medical equipment: In medical equipment such as blood analyzers, respiratory therapy devices and other equipment that require constant temperature, heaters are used to keep the equipment working within a suitable temperature range.

(3) Aerospace: Applied to satellite communications, wing heating, etc., it can melt snow and ice to ensure the normal operation of the equipment without increasing the load on the equipment.

Consider oxidation, service life, investment and maintenance costs.

Choose the appropriate installation method, regular maintenance, high-quality materials, and do a good job of pre-oxidation.

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China