Flexible Printed Circuit Board (FPC), commonly known as "flexible board," is a type of printed circuit board made using a flexible insulating substrate (mainly polyimide or polyester film). It possesses many unique advantages that traditional rigid printed circuit boards do not have, such as the ability to bend, wrap, and fold freely. The application of flexible pcb can greatly reduce the size of electronic products, fitting the trend of electronic products moving towards high density, miniaturization, and high reliability. Therefore, FPC is widely used in fields or products such as aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras, etc.

However, to ensure the high efficiency of electronic devices, the interference resistance of FPC must be considered, which is closely related to the design of FPC circuits. The following will introduce some effective FPC anti-interference measures:

In flexible circuit board design, if both logic circuits and linear circuits are present, they should be arranged separately as much as possible. The grounding of low-frequency circuits should use single-point parallel grounding. If actual wiring is difficult, some circuits can be connected in series first and then parallel grounded. This design can effectively reduce interference between signals.

When the flexible circuit board is composed only of digital circuits, the grounding circuit should be arranged in group loops. This design can significantly improve the noise resistance of the flexible printed circuit board and effectively reduce the impact of external interference on the circuits.

While meeting performance requirements, try to reduce the number of crystal oscillators for microcontrollers and choose low-speed digital circuits. This can reduce radiation interference caused by high-speed signals, helping to improve overall anti-interference performance.

Try to solder IC devices directly onto the flexible circuit board and avoid using IC sockets. Direct soldering can reduce instability and contact issues caused by sockets, improving circuit reliability.

To achieve better circuit performance, components and wires must be reasonably laid out. After determining the size of the FPC, special attention should be paid to the location of special components. According to the functions of the circuit, carefully arrange all components to ensure smooth signal flow, which is a necessary choice for an excellent design.

With the above anti-interference measures, the anti-interference capability of FPC can be greatly improved, ensuring the stability and reliability of electronic products. In future electronic product development, we need to fully consider these factors to adapt to the rapid development of electronic technology and market demands.

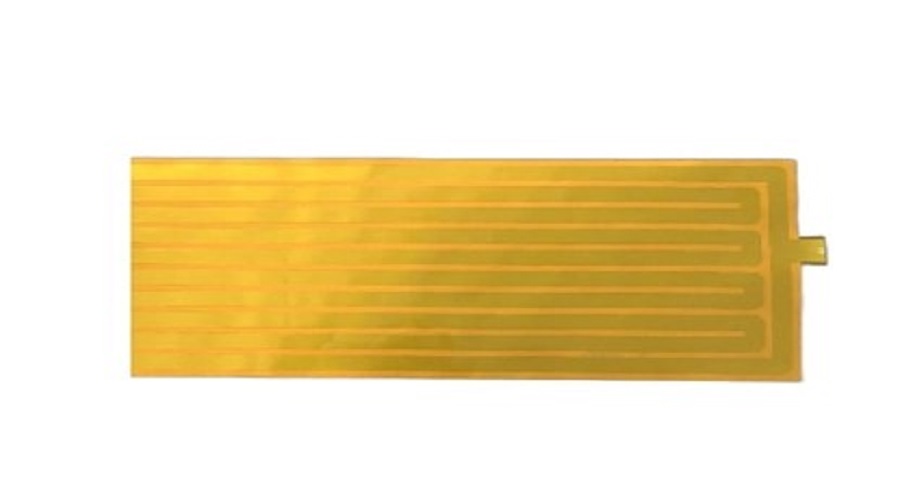

Advantages and Applications of Polyimide Film Heater

16 Apr 2025

Polyimide film heater is a high-performance electric heating element made by using polyimide film as the outer insulation layer, metal foil or metal wire as the inner conductive heating element, and b...

Advantages and Applications of Polyimide Film Heater

16 Apr 2025

Polyimide film heater is a high-performance electric heating element made by using polyimide film as the outer insulation layer, metal foil or metal wire as the inner conductive heating element, and b...

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China