FPCFlexible Printed Circuit is a type of printed circuit board made with polyimide or polyester film as the base material, offering high wiring density, lightweight, and thin thickness. It is mainly used in products such as mobile phones, tablets, medical devices, LEDs, automotive electronics, and smart wearables. FPC can be classified into single-sided FPC, double-sided FPC, multi-layer FPC, and rigid-flex FPC.

Single-sided FPC has a layer of chemically etched conductive pattern, where the conductive pattern layer consists of rolled copper foil. The insulation base material can be polyimide, polyethylene terephthalate, aromatic polyamide ester, and polyvinyl chloride. Single-sided FPC can be further divided into the following four subcategories:

1. Single-sided connection without cover layer

The conductive pattern is on the insulation base, with no cover layer on the conductor surface. The interconnection is achieved by soldering, welding, or pressing.

2. Single-sided connection with cover layer

Compared to single-sided connection without cover layer, a cover layer is added on the surface of the conductor. The cover layer should expose the pads, and if simple, the end areas can remain uncovered.

3. Double-sided connection without cover layer

The connection pad can connect on both the front and back sides of the conductor. A via hole is made in the insulation base at the pad, which can be formed by punching, etching, or other mechanical methods in the required position of the insulation base.

4. Double-sided connection with cover layer

Different from double-sided connection without cover layer, the surface has a cover layer with via holes, allowing end connections on both sides while maintaining the cover layer. It is made of two layers of insulating material and one metal conductor layer.

Double-sided FPC has etched conductive patterns on both sides of the insulation film, increasing the wiring density per unit area. Metallized holes connect the conductive patterns on both sides of the insulation material, forming conductive pathways to meet the design and functional requirements of flexibility. The cover film can protect single and double-sided wires and indicate the placement of components.

Multi-layer FPC is made by laminating three or more layers of single-sided or double-sided flexible circuits together. Through drilling and plating, metallized holes form conductive pathways between different layers. This method eliminates the need for complex soldering processes. Its advantages include the lightweight of thin film base material and excellent electrical properties. Multi-layer FPC can be further divided into the following types:

1. Flexible insulation substrate product

It is manufactured on a flexible insulation substrate, with its finished product specified as flexible. This structure usually consists of multiple single-sided or double-sided microstrip flexible FPCs bonded together at their two sides, but not bonded at the center, thus maintaining high flexibility.

2. Soft insulation substrate product

It is manufactured on a soft insulation substrate, with its finished product not specified as flexible.

Rigid-flex FPC is a circuit board combining flexible and rigid circuit boards through processes like lamination, following relevant process requirements, which supports the characteristics of both FPC and PCB. Rigid-flex boards have both the characteristics of FPC and PCB. They can be used in products with special requirements, providing both flexible and rigid areas, aiding in saving internal space, reducing product volume, and improving product performance.

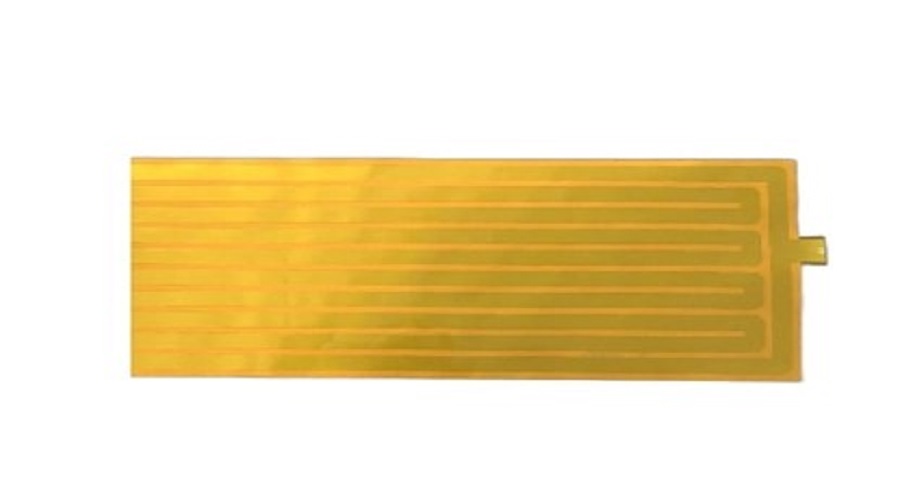

Advantages and Applications of Polyimide Film Heater

16 Apr 2025

Polyimide film heater is a high-performance electric heating element made by using polyimide film as the outer insulation layer, metal foil or metal wire as the inner conductive heating element, and b...

Advantages and Applications of Polyimide Film Heater

16 Apr 2025

Polyimide film heater is a high-performance electric heating element made by using polyimide film as the outer insulation layer, metal foil or metal wire as the inner conductive heating element, and b...

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China